A Digital Transformation Tool for Project Management, AI + Project Management, The Future is Here

Make Project Management Seamless, Connected, Permanent, and Transparent

Service-oriented manufacturing is an innovative model integrating manufacturing and services deeply. Its essence is the fundamental transformation from providing products to delivering "product-service systems". Centered on customers' ultimate value, it achieves full-lifecycle value co-creation through the seamless integration of manufacturing and high-value-added services.

In China, it has been elevated to a national strategic height. It is not only a key path for industrial upgrading and extending to the high-end of the value chain, but also a core engine for building a "manufacturing power" and supporting the "dual circulation" pattern, aiming to enhance the sustainable competitiveness of Chinese manufacturing in the global market.

Closely following national strategic needs and helping service-oriented manufacturing enterprises achieve high-quality development, Jumi Technology has built a project management system for service-oriented manufacturing enterprises. With "data, platform, ecology, connection, empowerment, and efficiency improvement" as its main characteristics, the system is positioned as a project management system in the digital and intelligent era.

The system focuses on improving "efficiency" in the project management process, and the precipitation, accumulation, and reuse of "data". It creates a cross-regional and cross-organizational project collaboration platform for service-oriented manufacturing enterprises; a project management platform that is visible, manageable, and retainable; an efficiency improvement platform for project communication, collaboration, and control; a data integration platform for the whole process and full-factor management of projects; and an ecological cooperation platform that connects and empowers project participants, realizing the organization online, communication online, collaboration online, business online, and ecology online of project management in service-oriented manufacturing enterprises.

Jumi Technology's service-oriented manufacturing project management system deeply integrates industry standard processes such as APQP (Advanced Product Quality Planning), IPD (Integrated Product Development), LTC (Lead To Cash), ITR (Issue To Resolution), as well as advanced project management methods such as TOC (Theory of Constraints) critical chain, creating a digital management solution covering the entire lifecycle and full factors of projects.

We focus on providing end-to-end project management systems for enterprises in the high-end equipment manufacturing industry that carry out total integrated general contracting and full life cycle management services, helping them achieve integrated management of project delivery and long-term service operations.

Not only provides equipment, but also is responsible for the design, construction, installation, commissioning of the entire production line or factory, up to the "turnkey".

provide customers with the whole process of service from equipment installation, operation and maintenance, maintenance, spare parts, upgrade to scrap and recycling.

Sell not single products, but customized solution packages (such as "smart factory solutions", "energy conservation and environmental protection solutions").

Manufacturers of heavy machinery, CNC machine tools, robots, aerospace, semiconductor equipment, printing machinery, and construction machinery.

Manufacturers of power generation equipment (wind power, photovoltaic), power transmission and distribution equipment, large motors, and energy management systems.

Manufacturers of commercial vehicles, railway locomotives, ships, and aerospace engines.

Smart home, smart medical equipment, smart building control system manufacturer.

Service-oriented manufacturing projects have both the complexity of "project-based manufacturing" and the intangibility of "service delivery", making their management difficulties particularly prominent:

Customer needs are often unclear in the early stage of the project and continue to evolve during the project process, leading to scope creep and frequent demand changes.

Projects involve internal departments such as design, production, procurement, and services, as well as external customers, suppliers, and partners. Collaboration is difficult, and information silos are serious.

How to plan, execute, and account for hardware delivery, software integration, and continuous service operations (such as remote monitoring, regular maintenance) under the same project framework is a major challenge.

Project income may come from initial sales, installments, service subscriptions and other models, while costs run through the entire process of R&D, manufacturing, delivery, operation and maintenance, and even remanufacturing. Financial accounting is extremely complex.

Each customized project is a process of knowledge creation. How to materialize the best practices, solutions, fault libraries, etc. in the project into organizational assets to avoid "reinventing the wheel".

Compound project managers and teams who understand both manufacturing technology, service business and customer management are needed, and such talents are scarce.

Service-oriented manufacturing projects have many external dependencies, long service cycles, and are affected by factors such as customer on-site conditions, making schedule control difficult.

There is an urgent need to take the project as the main line, and the project data and information scattered in various functional departments and IT systems can be flowed, connected and aggregated between various functional departments and IT systems.

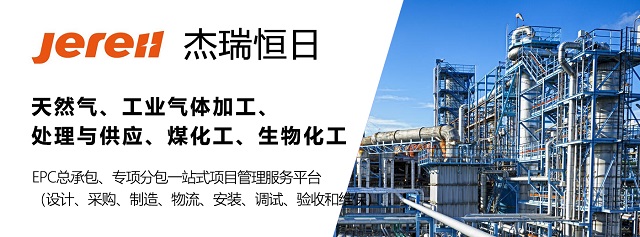

Empower business managers, quotation managers, project managers, design supervisors, procurement supervisors, manufacturing supervisors, logistics and transportation supervisors, planning specialists, cost supervisors, engineering supervisors, quality and safety engineers, and document engineers to improve cross-organizational, cross-departmental and cross-professional collaboration.

build bidding and quotation capabilities, design management capabilities, procurement management capabilities, manufacturing management capabilities, logistics and transportation management capabilities, on-site construction management capabilities, planning and schedule control capabilities, budget and cost management capabilities, contract performance capabilities, and QHSE management capabilities.

Through the reshaping of enterprise organizational boundaries and sharing digital services, customers, subcontractors, and suppliers can be included in the platform, forming an ecosystem, and forming an open innovation ecology.

Improve service experience and bring revenue growth: Customer-centric, provide high-quality and efficient project construction, project delivery and project manufacturing services to help the company's revenue growth.

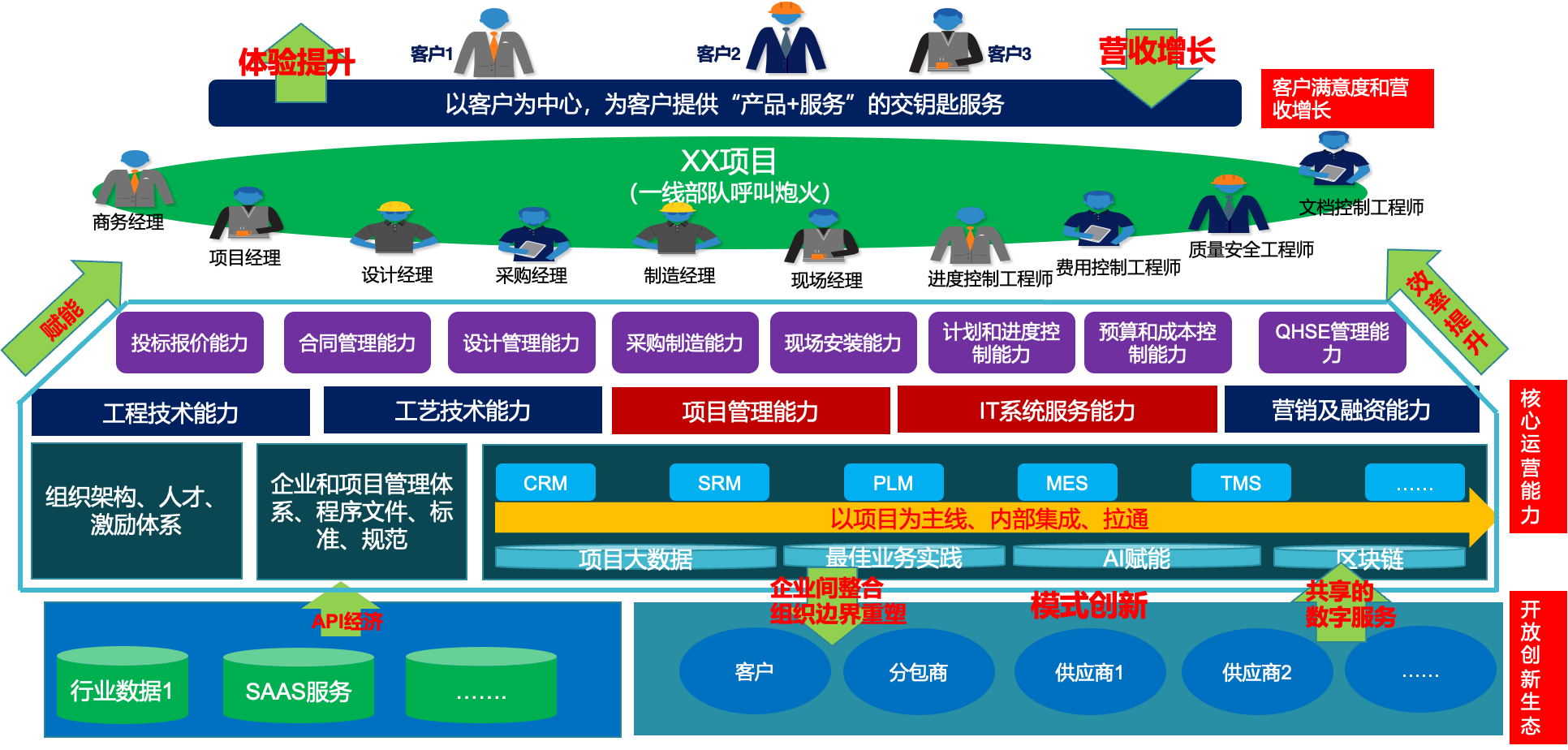

The platform adopts private deployment and multi-tenant architecture. Project participating units can be incorporated into the platform through enterprise registration and review to collaborate and complete project delivery.

Includes business component libraries, business process libraries, data template libraries, and standard specification libraries for multiple service-oriented manufacturing industries and different project types.

Configure different business components, business processes, data templates, and standard specifications for different project types. If insufficient, extended development can be carried out through the extended development platform to achieve one platform with N types of applications.

Portal, PC terminal, APP terminal, and interface integration with third-party systems, including personal center, role center, business center, collaboration center, and project center.

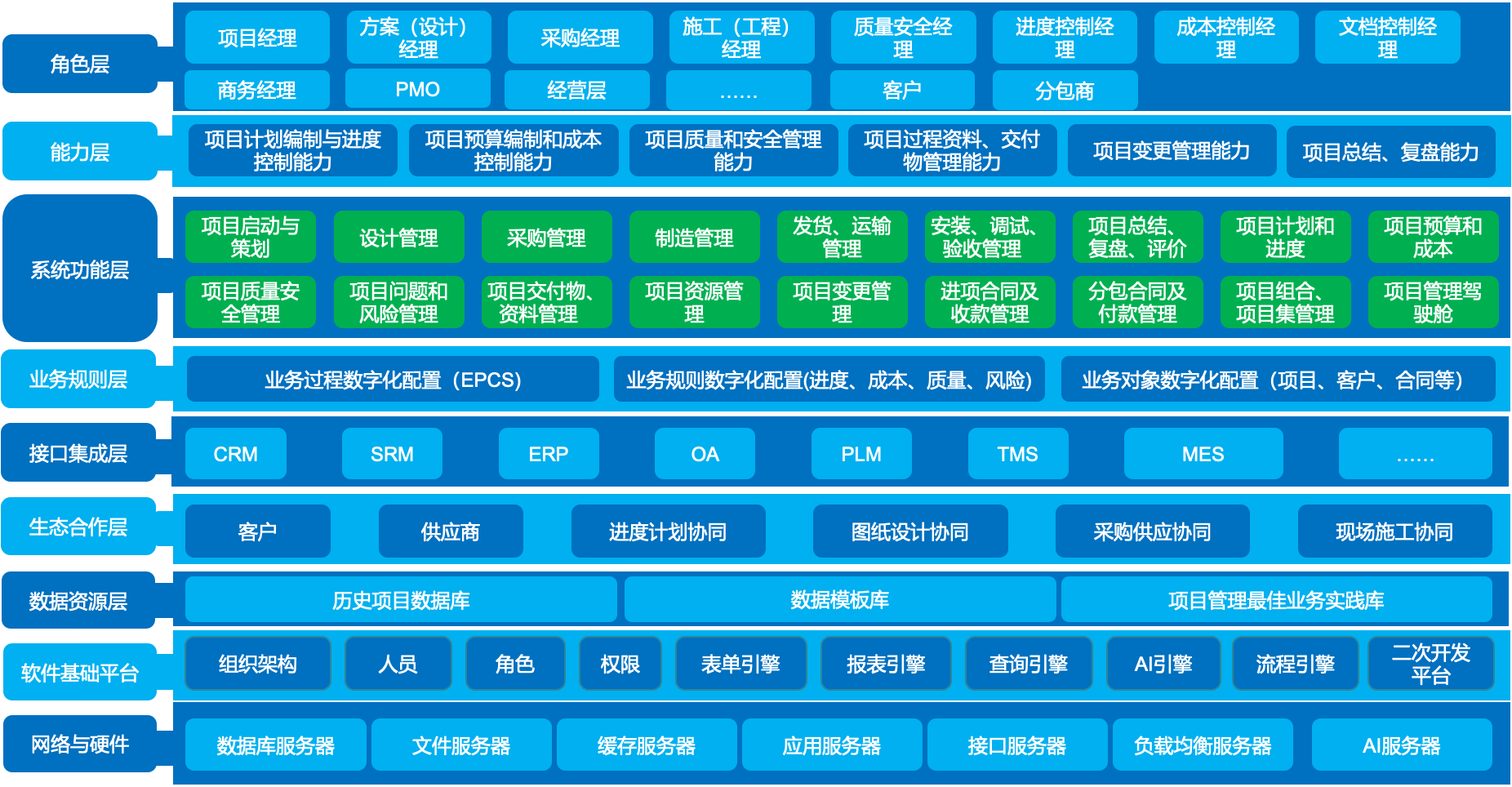

Project manager, solution (design) manager, procurement manager, production manager, construction (engineering) manager, quality and safety manager, schedule control manager, cost control manager, document control manager, business manager, PMO, management layer, customer, subcontractor.

Project initiation and planning capabilities, project plan formulation and schedule control capabilities, project budget formulation and cost control capabilities, project quality and safety management capabilities, project on-site installation and commissioning management capabilities, project process data/deliverable management capabilities, project change management capabilities, project resource management capabilities, and project summary and review capabilities.

Project initiation and planning, design management, procurement management, manufacturing management, delivery and transportation management, installation, commissioning and acceptance management, project summary, review and evaluation management, project plan and schedule management, project budget and cost management, project quality management, project HSE management, project problem management, project risk management, project deliverable management, project resource management, project change management, incoming contract and collection management, subcontract contract and payment management, project portfolio and program management, project management cockpit.

Digital configuration of business processes (EPCS), digital configuration of business rules (schedule, cost, quality, risk), digital configuration of business objects (projects, customers, contracts, etc.).

CRM, SRM, OA, PLM, TMS, MES, ERP.

Customers, suppliers, schedule planning collaboration, drawing design collaboration, procurement and supply collaboration, on-site construction collaboration.

Historical project database, data template library, project management best practice library.

Organizational structure, personnel, roles, permissions, task activity engine, form engine, report engine, query engine, AI engine, process engine, secondary development platform.

Database server, file server, cache server, application server, interface server, load balancing server, AI server.

Through project management cockpit, digital large screen, video surveillance, BIM+, and automated periodic reporting, decision-makers and management can see the execution of annual investment plans, as well as the progress, investment, quality, safety, problems and risks of single projects, multiple projects, project groups and project portfolios.

Based on goal management and cybernetics, achieve effective control of project plans and progress, budgets and costs, quality gates, changes and visas, and monitor and alert project progress, costs, quality gates, documents, issues, and risks.

Through three databases - the ongoing project database, the historical project database after project closure, and the project management best practice library summarized and refined, achieve the accumulation and reuse of project data.

Project participants conduct online discussions and communications on business objects such as progress, costs, deliverables, and changes, including text, files, emails, etc. Communication process records are permanently stored.

With projects as the main line, plans as the leader, and tasks as the driver, through critical chain project management, identify business bottlenecks, resolve blockages, increase project flow, and achieve orderly and efficient collaboration across organizations and departments.

Through hierarchical and layered plan management, rolling plans, interface plans, PDCA cycles for quality and safety, and project document control, transform the transmission of data and information from traditional offline to online, effectively improving the efficiency of project control.

The project management system is essentially a project-oriented system that integrates, connects, pulls, and aggregates data with the existing IT system of the enterprise. The core task is to "take the project as the main line of guidance, overall planning, and task-driven, realize the transmission and flow of project data and information in various professional systems according to the project stage and project tasks, avoid information islands, and improve collaboration efficiency." These systems include: ERP system, procurement system, OA system, BPM system, MDM system, financial system, fund payment system, enterprise network disk, contract and legal management system, budget system, enterprise WeChat, DingTalk, Feishu system, etc.

With the project as the carrier and the portal as the entrance, enterprises in the upstream and downstream industrial chains (such as consulting companies, designers, supervisors, and subcontractors) are included in the platform, and through enterprise registration and settlement, from internal collaboration to external collaboration, an ecosystem is built. Business scenarios of external collaboration include: cross-organizational multi-level and multi-level planning and schedule control, online document sending and receiving, online design collaborative management, online bidding, online quality and safety problem rectification, online change visa approval management, online output value filling and payment application, etc.

Chint New Energy, Jiadu Technology, Shiyuan Technology and other customers have established a project planning and schedule control system, effectively shortening the project period. The project plan achievement rate has increased from 70% to 85%, an increase of 15%.

Jiadu Technology, Chongqing Power Construction, Topstar and other customers have established a project budgeting and cost control system, refined management of project costs, and reduced the cost of a single project by more than 5%.

Jereh Hengri, SUMEC Group, Zhibang Home Furnishing and other customers have effectively improved the management level of the construction site through the quality and safety inspection and rectification of non-conforming items on the APP side, and the quality and safety management level has increased by 15%.

Customers such as Jiadu Technology, Tostar, and Shanghai Electric Digital have realized cross-departmental collaboration in the whole process from project start-up, project execution, and project closure, as well as cross-organizational collaboration with all parties involved in the project, and the overall collaboration efficiency has been increased by 15%.

By providing customers with high-quality and efficient project construction services, customer satisfaction is greatly improved. Shanghai Electric Digital Technology, Zhengzhou Digital Intelligence and other enterprises have opened their project management platforms to customers, and customer satisfaction has increased from 50% to 75%.

Through the digital transformation of project management, the company's core operational capabilities are built to help revenue growth. Jiadu Technology has been building a project management platform since 2015, and its annual turnover has increased by more than 10%.

| Functional Module | Module Description |

|---|---|

| Customer Management | Potential customers, formal customers, invalid customers; 360-degree customer information query; customer visit plans, visit logs, praises, complaints, follow-ups, and satisfaction surveys. |

| Market Development | Project leads, project opportunities, follow-up records; evaluation and conversion of project leads, opportunities, and bidding projects; sales funnel analysis, strategic sales, sales stage and sales activity settings. |

| Project Investment and Financing Management | Investment lead management, investment plan management, project financing plan and financing progress management. |

| Project Creation | Project numbering rules, project creation, project information adjustment, interface with MDM system. |

| Project Initiation and Planning | Project manager appointment, personnel transfer, project team member maintenance, project handover, project kick-off meeting, project collaboration units, project address book, overall project planning and project sub-planning. |

| Project Preparatory Work, Approval and Compliance Procedures Management | Project pre-approval plan, pre-approval procedure handling, pre-approval document filing. |

| Project Design Management | Special design plans, design commissions or design contracts, design drawing upload, download, distribution and reception, design review (online drawing viewing and annotation), design disclosure, and design changes. |

| Supplier Access and Evaluation Management | Supplier access invitation, inspection score sheet, access application, and supplier database management; daily monitoring, supplier evaluation template, evaluation, activation, blacklisting, and special approval for use; docking with Qichacha; 360-degree supplier information query. |

| Project Bidding and Procurement Management | Special procurement plan; contract planning, bidding document issuance, query and reply, bidder quotation, bid evaluation experts, bid opening records, bid determination review, bid winning announcement, bid winning notice; procurement documents and data; collection and refund of bid security. |

| Material code library | material classification, material classification signature code, automatic generation of material library (Cartesian product), material library query, material code application, docking with ERP material library, and 100,000 material codes provided by Polymeter. |

| Material budget and procurement requirements | material budget preparation, material budget change, material budget statistics, material change records, material cost control table. Procurement requirements, procurement demand changes. |

| Material procurement | delivery early warning setting, procurement bidding scoring rules, project procurement control price, purchase package, online inquiry, supplier quotation, procurement bidding, framework contract, purchase order, material procurement progress tracking, material procurement quantity tracking, order delivery tracking. |

| Warehouse management | inspection into the warehouse, transfer into the warehouse, collection and delivery, material return, material return, material inventory, waste material disposal, transfer and delivery, on-site material inquiry, company material warehouse. |

| Equipment supervision management | equipment supervision quality inspection plan, equipment supervision quality inspection, equipment supervision quality rectification, equipment supervision quality acceptance, equipment supervision quality evaluation overview. |

| Production management | production special plan, acquisition or tracking of the progress of production special plan, coordination of production special plan, monitoring and early warning, adjustment and assessment of production special plan, inventory product management, and issuance product management. |

| Shipment management | project demand information form, shipment special plan, batch logistics information, shipment receipt, and commodity inventory. |

| Project Construction Management | Special construction plan, construction scheme, construction organization design, construction preparation, start-up management, shutdown management, resumption management; technical disclosure, construction log, construction documents and data. |

| Project Commissioning and Trial Operation Management | Special commissioning and trial operation plan; commissioning scheme, commissioning records, commissioning summary; trial operation scheme, trial operation records, trial operation summary; problem rectification. |

| Project Completion Acceptance Management | Phased acceptance, pre-acceptance, special acceptance, completion acceptance; handover plan, handover list; physical handover; acceptance records. |

| Fixed Asset Transfer Management | Preparation and adjustment of fixed asset list, asset evaluation, asset registration and notification; integration with fixed asset management system. |

| Project Summary and Post-Evaluation Management | Professional summary reports, project summary report, project summary meeting and meeting report; project post-evaluation records. |

| Project Handover Management | Handover plan, handover list; physical handover; acceptance records. |

| Project Warranty Period and Operation and Maintenance Management | Operation and maintenance projects, operation and maintenance work orders, fault reporting; maintenance scheme; maintenance budget preparation; issuance of maintenance task orders. |

| Project Closure Management | Outgoing contract settlement, outgoing contract closure; final accounts of completed projects; project closure checklist; project closure. |

| Functional Module | Module Description |

|---|---|

| Project Plan Formulation and Progress Control | Standard task library, plan templates; formulation and approval of key milestone plans, master control plans, and special plans; multi-level plan linkage; task push, task execution and feedback; progress monitoring and early warning, plan adjustment, and progress assessment. |

| Functional Plan Formulation and Progress Control | Standard task library, plan templates; formulation and approval of functional plans; task push, task execution and feedback; progress monitoring and early warning, plan adjustment, and progress assessment. |

| Project Bill of Quantities Management | Project bidding bill of quantities, project contract bill of quantities; reporting, review, and confirmation of project bill of quantities completion status; summary statistics of completed project output value. |

| Project Outgoing Contract Management | Outgoing contract entry and review, outgoing contract accounting book; contract changes, supplementary agreements; contract claims, counterclaims; contract rewards and penalties; contract termination, suspension, resumption; contract settlement; contract closure checklist, contract closure. |

| Project Contract Payment Management | Confirmation of contract payment nodes; reporting and confirmation of contract bill of quantities; contract payment node accounting book, contract bill of quantities payment accounting book; contract payment application, non-contract payment application; payment application accounting book, invoice reception. |

| Project Fund Plan Management | Binding of contract payment nodes, bill of quantities with project progress plan; project monthly fund plan, company monthly fund plan; project annual fund plan, company annual fund plan. |

| Project Budget and Cost Control | Project expense items, project expense worksheet templates; definition of project expense items and project expense worksheets; formulation and approval of project estimation, preliminary estimate, and budget; project actual cost collection; project cost overrun early warning. |

| Project Document Management | Project document directory and document templates; drafting, approval, distribution, reception, borrowing, filing, query and retrieval, authorization, download, and version management of project documents; online document co-editing, project document control list. |

| Project Quality Management | Quality planning, quality standard library, quality inspection templates; quality inspection plan, quality inspection (APP terminal), unqualified item rectification, statistical analysis. |

| Project Safety, Environment, and Occupational Health Management | HSE inspection templates, start-up filing, high-risk projects, safety education, safety inspections, hidden danger rectification, mechanical equipment, special operations personnel, emergency response, accident quick report, safety penalties, work permits, team morning meetings, etc. |

| Project Inspection Management | Project inspection templates, project inspection plans, project inspections, project inspection rankings, quality unqualified item rectification, safety hidden danger rectification. |

| Project Communication Management | Project address book; announcements, news, notifications; work contact forms, meeting management, meeting minutes, tracking of meeting resolutions; incoming document management, outgoing document management. |

| Project Problem/Coordination Management | Proposing, solving, and closing problems (coordination required items); problem (coordination required items) list; conversion of problems (coordination required items) to risks; precipitation of problems (coordination required items) into lessons learned. |

| Project Risk Management | Risk list templates; risk identification, risk monitoring, risk closure; early warning settings for schedule delays, cost overruns, personnel overload, quality and safety risks. |

| Project Change Management | Contact forms, change orders, visa forms; project plan changes, project budget changes, project deliverable changes, project personnel changes, project change history sheet. |

| Project Phase and Status Management | Project phase templates, project phase definition, project phase review, project node review; project start-up, project suspension, project resumption, project termination. |

| Lessons Learned Management | Lessons learned horizontal expansion matrix; precipitation and approval of lessons learned; horizontal expansion of lessons learned; query of lessons learned library; intelligent push of lessons learned. |

| Program and Portfolio Management | Program and portfolio definition; project priority ranking; program and portfolio data analysis. |

| Project Periodic Reports | Definition of periodic report elements; setting of periodic report templates; automatic generation, sending, and viewing of periodic reports. |

| Project Management Cockpit | Overall dashboard, multi-project/program, portfolio, single project dashboard; special dashboards for project progress, investment, contracts, quality, safety, and project documents; special dashboards for project approval, design, procurement, construction, acceptance, problems, and risks. |

| Business Component Library | PC terminal business components, APP terminal business components, custom component library; project progress management business components, project cost management business components, project quality management business components, project document management business components, etc. |

| Business Process Library | Business process drawing, business process release; project delivery visualization; data flow automation; identification of project delivery bottlenecks. |

| Standard Specification Library | Classification of standard specifications (national, industry, enterprise); upload of standard specifications; query and retrieval of standard specifications; borrowing and cancellation of standard specifications. |

| Historical Project Database | Databases of historical project progress, cost, quality, safety, contracts, documents, etc.; query, retrieval, and reuse of historical project data. |

| Data Template Library | Project role templates, project phase templates, project plan templates, expense item templates, drawing document directory templates, project quality inspection templates, project safety inspection templates, project inspection templates, contract templates, etc. |

| BIM+ | Integration of BIM engine; lightweight browsing of BIM models; integration with project progress, cost, and document data. |

| APP Terminal | Pending approvals, responsible matters; message notifications and early warnings; task push, progress feedback; quality inspection, photo taking, rectification; safety inspection, photo taking, rectification; attendance checking and sign-in of project department and subcontractor personnel; viewing of project center and cockpit data. |

Jumitech has long been committed to the research of project management theories and practices. We have deeply insight that the application of AI in project management is evolving from a tool to a partner, and even to a strategic core:

ChatBots: Natural language dialogue. Automate repetitive tasks and free up human resources.

Reasoners: Basic reasoning and question answering. Provide data analysis and preliminary suggestions to assist decision-making.

Agents: Execute tasks on behalf of users with independent action capabilities. Deeply participate in processes for real-time collaboration and reminders.

Innovators: Participate in invention and creation to enhance human creativity and innovation capabilities. Provide professional-level management suggestions and solutions in specific fields.

Organizations: Undertake the entire organizational function to independently manage and execute complex operations. Conduct resource coordination, strategic alignment, and effectiveness evaluation from an organizational-level project management perspective.

Jumitech XPM+ platform deeply integrates artificial intelligence technology to create an intelligent application matrix covering the entire project lifecycle. The following are detailed explanations of the core AI functions that have been implemented:

Use natural language processing and machine learning models to conduct multi-dimensional intelligent evaluation of project proposals, analyze strategic compliance and potential risks, provide data-driven project approval for decision-makers, and improve investment success rate from the source.

Based on historical project data and industry best practices, it automatically generates a first draft of a project plan with a rigorous structure and reasonable task decomposition, embedded with intelligent scheduling logic, significantly improving the efficiency and scientificity of planning preparation.

Acting as a "senior planning expert", it intelligently identifies logical conflicts, resource overload, and critical path risks in the plan, and provides specific optimization suggestions to ensure a robust and reliable project baseline.

Build a dynamic "resource smart brain" to monitor resource load and skill matching in real time, simulate the impact of different scheduling schemes, and recommend optimal solutions to maximize resource utilization.

By analyzing historical cost structure and market data, it quickly generates detailed and reasonable budget drafts, improving the accuracy of cost forecasting and reducing the blindness of budgeting.

Automatically detect outliers and potential over-fulfills in the budget, propose cost optimization plans through multi-scenario simulation, and strengthen project cost control capabilities.

According to project types and industry specifications, standardized document catalog frameworks are intelligently generated with one click to ensure the standardization and integrity of project document management.

Intelligently generate high-quality first drafts of key deliverables based on project tasks and knowledge assets, freeing up the productivity of project members and allowing them to focus on creative work.

Preset quality standards, automatically verify the consistency and integrity of deliverables, quickly identify errors and omissions, and act as the first intelligent quality checkpoint.

Deeply integrate speech recognition technology with project management scenarios, and the spoken content can be automatically converted into structured reports, revolutionizing the efficiency and experience of information entry.

In mobile office scenarios, update task progress in real time through voice, and automatically synchronize information to the system, ensuring seamless collaboration and real-time accuracy of data.

Automatically aggregates project data according to preset periods and generates professional reports with pictures and texts within seconds, allowing managers to grasp the overall picture of the project at any time and with one click.

Create a "talking" project database that supports natural language questions (such as "Project A's cost deviation rate this month?" Get accurate answers instantly and democratize data.

Visualize complex data relationships and automatically generate the most suitable charts (such as burndown charts and resource bar charts) according to instructions, allowing you to understand the project status at a glance.

Serve as the "intelligent physical examination center" of the project, continuously monitor key indicators, quantify health scores and proactively identify risks, provide root cause analysis and response suggestions, and achieve a leap from passive response to active management.